P500+

PECVD

Thin Film Solutions Ltd provides customised, reliable depositions systems for optical, engineering, decorative, photovoltaic and semiconductor applications.

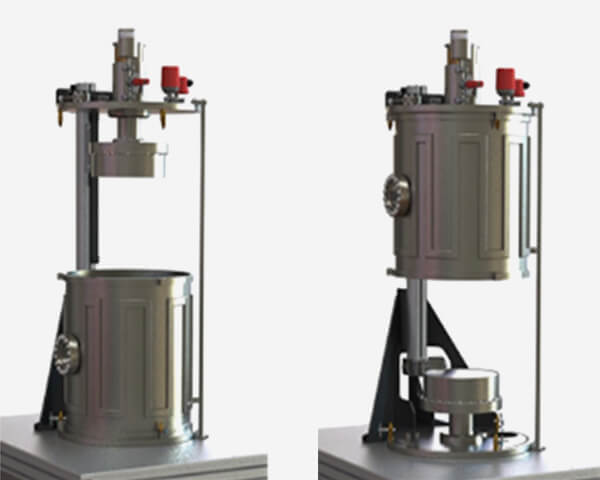

Our RF plasma deposition systems with MOCVD precursor delivery and low frequency injection options provide flexibility for process implementation onto flat and non-conformal geometries for a wide variety of processes. System configurations are available with various electrode diameters to suit R & D or production.

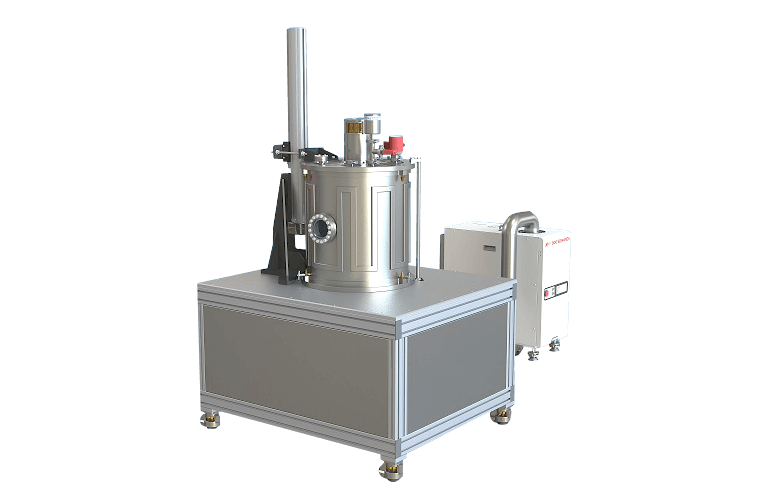

Complete Machine

The Main Features

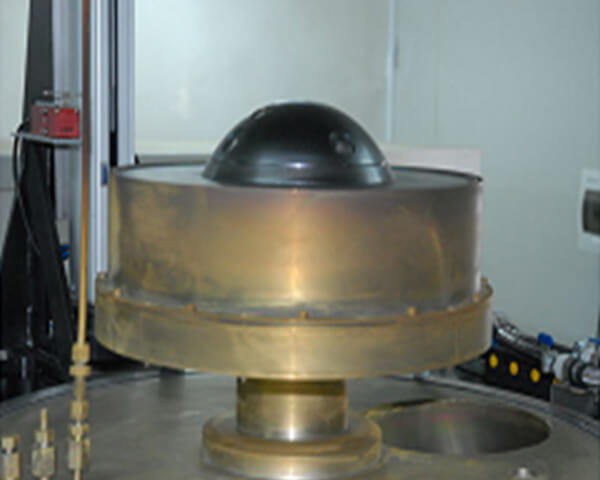

Electordes

- Retrofittable electrodes

- Electrodes 100mm to 1m

- Heated electrode option

- Adjustable separation

- Auto-tune matching

- Low freq injection option

Automatic Control

- Automated control system

- Automatic Pressure Control

- User friendly interface

- Datalogging

- Flexible recipe set-up

- Off-line recipe editing

Pump Options

- Various Pump Options: Dry, turbo, toxic/pyrophoric gas compatible

- Wide process pressure range: 10⁻⁶ to 10⁻² mbar

Ease of Access

- Easy access to top/ bottom electrodes

- Safe configuration for toxic/ pyrophoric gas use

- Full safety interlocked

- Easy access for cleaning

RF PECVD System with 19” Control Rack

- Control over stoichiometry via process conditions. Heated option to 500°C with proprietary thermodynamic design to ensure substrate at temperature. Electrode separation adjustable from 100 to 250mm

- Offers a wide range of material deposition, including: SiOx, SiNx, SiOxNy, Si3N5, SiC, a-Si:H, SiO2, Ta2O5, TiO2

- Diamond-Like-Carbon, fully compliant with wide range of industry standard environmental/ durability tests

- Phosphide based coatings

- Self cleaning features